|

| AI generated Image of BMS |

A Battery Management System (BMS) is an electronic system that manages a rechargeable battery (cell or battery pack), by monitoring its state, controlling its environment, and protecting it from operating outside its safe operating area.

1. Battery Monitoring Unit (BMU)

The BMU is the "sensory" part of the BMS. It's typically distributed throughout the battery pack, with individual monitoring circuits for groups of cells or even individual cells in high-precision systems.

These circuits are connected to a central communication bus that relays data to the Battery Control Unit (BCU). Components:

Voltage Sensors: High-precision analog-to-digital converters (ADCs) that measure the voltage of each cell or cell group. Accuracy is crucial here, as even small voltage differences can indicate significant state-of-charge variations.

Current Sensors: Devices that measure the current flowing into and out of the battery pack. Common types include:

Shunt Resistors: Measure voltage drop across a small resistor in the current path. Simple and cost-effective but can generate heat.

Hall Effect Sensors: Measure the magnetic field generated by the current. More accurate and efficient than shunt resistors.

Current Transformers: Measure the current by inducing a current in a secondary winding. Used for high-current applications.

Temperature Sensors: Thermistors or thermocouples placed at strategic locations within the battery pack to monitor temperature.

Working:

- Voltage sensors continuously measure the voltage of each cell or cell group.

- The current sensor measures the total current flowing in and out of the battery pack.

- Temperature sensors monitor the temperature at various points in the pack.

- The BMU converts these analog measurements into digital signals using ADCs.

- This digital data is then transmitted to the BCU via a communication bus (e.g., CAN, SPI).

2. Battery Control Unit (BCU)

The BCU is the "brain" of the BMS. It's a central processing unit that receives data from the BMU, makes decisions, and controls the battery's operation.

Components:

Microcontroller (MCU): A powerful processor that executes the BMS software, performs calculations, and controls the other components.

Memory: Stores the BMS software, battery parameters, and historical data.

Communication Interfaces: Allow the BCU to communicate with the BMU, other vehicle systems (e.g., VCU), and external devices (e.g., chargers).

Gate Drivers: Control the switching of power electronic devices (e.g., MOSFETs) in the charging and discharging circuits.

Working:

- The BCU receives data from the BMU (voltage, current, temperature).

- The MCU processes this data to:

- Calculate State of Charge (SOC) and State of Health (SOH).

- Determine if any protection thresholds have been exceeded.

- Implement cell balancing algorithms.

- Control the charging and discharging process.

- The BCU sends control signals to:

- Cell balancing circuits: To equalize cell voltages.

- Charging/discharging circuits: To regulate current and voltage.

- Cooling/heating systems: To maintain optimal temperature.

- External systems: To communicate battery status and receive commands.

3. Cell Balancing Circuit

Cell balancing circuits are integrated into the BMU or as separate modules. They are connected to each cell or cell group.

Components:

Passive Balancing: - Resistors: Used to dissipate excess energy from higher-voltage cells.

- Switches (e.g., MOSFETs): Control the connection of the resistors to the cells.

Active Balancing: - DC-DC Converters (e.g., buck-boost converters): Transfer energy between cells.

- Capacitors or Inductors: Used as energy storage elements in the transfer process.

- Switches (e.g., MOSFETs): Control the flow of energy between cells.

Working:

Passive Balancing: When a cell's voltage exceeds a certain threshold, the corresponding switch is closed, connecting the resistor. The resistor dissipates the excess energy as heat, lowering the cell's voltage.

Active Balancing: Energy is transferred from higher-voltage cells to lower-voltage cells using the DC-DC converter and energy storage elements. This is a more efficient method as it doesn't waste energy as heat.

4. Protection Circuit

The protection circuit is typically implemented within the BCU and uses dedicated hardware and software to ensure fast and reliable response to fault conditions.

Components:

Comparators: Compare measured values (voltage, current, temperature) to predefined thresholds.

Logic Gates: Combine the outputs of the comparators to generate protection signals.

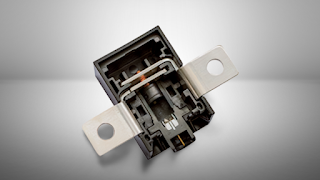

Switches (e.g., MOSFETs, relays): Disconnect the battery from the load or charger in case of a fault.

Working:

- Comparators continuously monitor voltage, current, and temperature.

- If any of these parameters exceed their safe limits, the comparators trigger a protection signal.

- Logic gates combine these signals to generate a final protection command.

- This command activates the switches, disconnecting the battery to prevent damage.

5. Communication Interface

The communication interface is implemented within the BCU and provides connectivity to external systems.

Components:

Communication Controllers: Implement communication protocols such as CAN, LIN, SPI, or UART.

Transceivers: Convert digital signals into signals suitable for transmission over the communication bus.

Working:

- The BCU formats data into messages according to the communication protocol.

- The transceiver converts these messages into electrical signals.

- These signals are transmitted over the communication bus to other systems.

- The receiving system decodes the messages and extracts the data.

Benefits of using a BMS

Using a BMS has many benefits, including:

- Increased battery life: By protecting the battery from operating outside its safe operating area, the BMS can help to extend the battery's life.

- Improved battery performance: By ensuring that all cells in the battery pack are balanced, the BMS can help to improve the battery's performance.

- Enhanced safety: The BMS can help to prevent battery fires and other safety hazards.

- Reduced warranty costs: By protecting the battery from damage, the BMS can help to reduce warranty costs.